Reduced Ambient Pressure Improves Solid-State Laser Performance & Reduces Spatter

By Christian Börner and Klaus Dilger

In the German publicly funded research project “LaReD,” investigations are conducted to exploit the potential of high brilliance solid-state lasers and enhance the quality of the joints they produce. This project is being carried out at the Institute of Joining and Welding in Braunschweig, Germany, and is supported by the German Welding Society.

The objective is to enable the use of these modern solid-state lasers for components with the highest requirements on weld seam quality — e.g., in gearbox manufacturing for the automotive industry. In this case, a process environment featuring reduced pressure during the welding procedure constitutes the crucial difference when producing high-quality weld seams. To be clear, this is not a vacuum, but only a reduced pressure. The characteristics of the weld quality improvement already occur under a reduced pressure of about 100 hPa and are fully completed in a pressure range from 10 to 1 hPa.

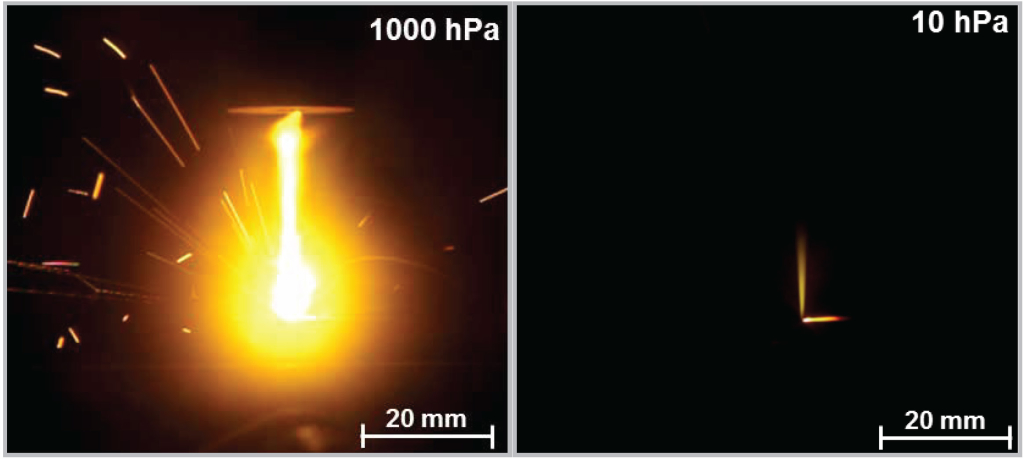

During the laser beam welding process, local vaporization occurs in the focus due to the high intensity, which results in the formation of a capillary. The metal vapor escapes from the keyhole with excessive pressure, which can be seen above the joining area as a bright light. This is also called a metal vapor plume (Figure 1). The bright light of the plume is caused by the temperature radiation of condensed particles in the welding fume. Rising welding fumes and the included particles absorb part of the laser beams. This leads to an interaction between the incident laser beam and condensed particles in the welding fume. The influence on the laser beam due to its interaction with the metal vapor plume was verified by means of test laser beams. A clear scattering of the visible laser beams onto a target is caused by this interaction.

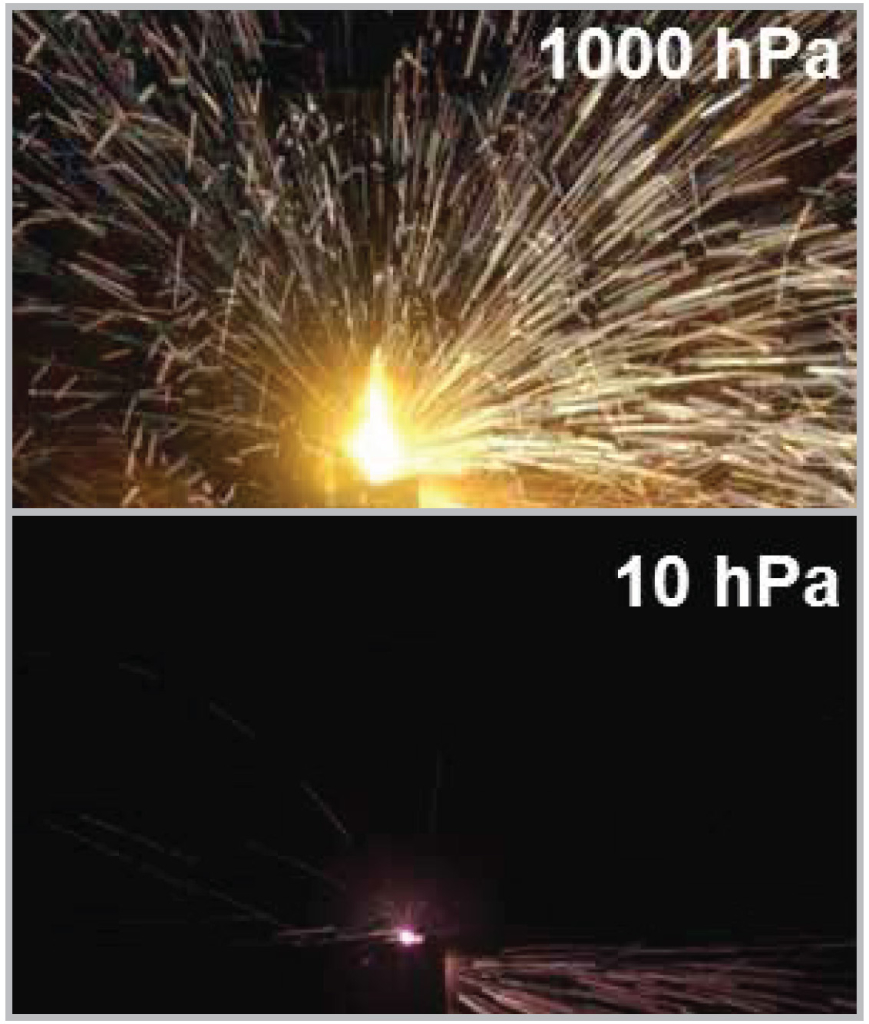

In laser beam welding, the exiting metal vapor hits the molten layer at the back wall of the capillary and in overcoming the surface tension causes the separation of welding spatters. In production, spatters lead to a number of serious problems, such as depositions and adhesions on the plate surface and additional contamination of the protective glass. Furthermore, welding spatters constitute a loss of material in the seam, which may lead to external irregularities. Disadvantages are a weakened weld seam and an adverse effect on the service life of the component. In laser beam welding under atmospheric pressure, a very strong spattering can be observed. The spattering clearly decreases on the plate surface when reducing the pressure to 10 hPa (Figure 2).By decreasing the ambient pressure, the bright light of the plume is clearly reduced. In a pressure range of 10 hPa and below, the lightning is practically no longer visible (Figure 1). In addition, an influence by scattering of the visible test laser beam can no longer be identified. The air molecules slow down the metal vapor to a much lesser extent when exiting the keyhole and it can thus exit upward freely and directionally. Furthermore, the evaporation temperature of iron — which is lower at reduced pressure — also leads to lower temperatures of the metal vapor particles and lets them shine with reduced intensity. The interaction between the laser beam and metal vapor is suppressed in the welding process at reduced pressure in such a way as to lead to various characteristic particularities in the welding process and welding result, which are described in the following by means of full-penetration weldings in 3 mm thick case hardening steel of the quality 16MnCr5.

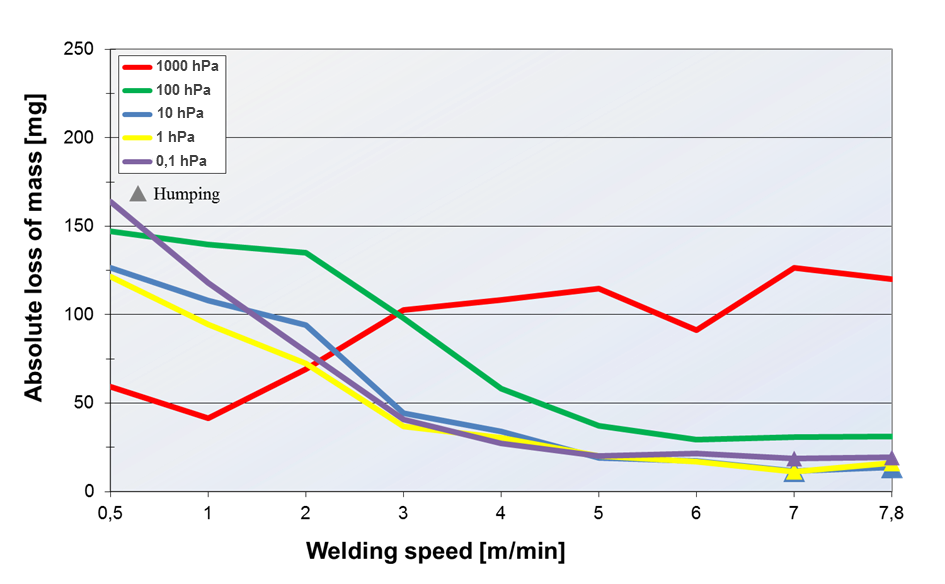

Weld specimens were weighed before and after welding by using a high-precision scale. Spattering is characterized by the weight loss of the specimen plates (Figure 3). Reduction of the pressure to 10 hPa goes hand in hand with the reduction of spattering. In addition, the characteristic process indicates a reduction of spattering with increasing feed rate. A further decrease of the pressure does not significantly influence the occurrence of spattering. The reduction of spattering at reduced pressure occurring in particular with high welding speeds is again a result of the suppression of the metal vapor plume.

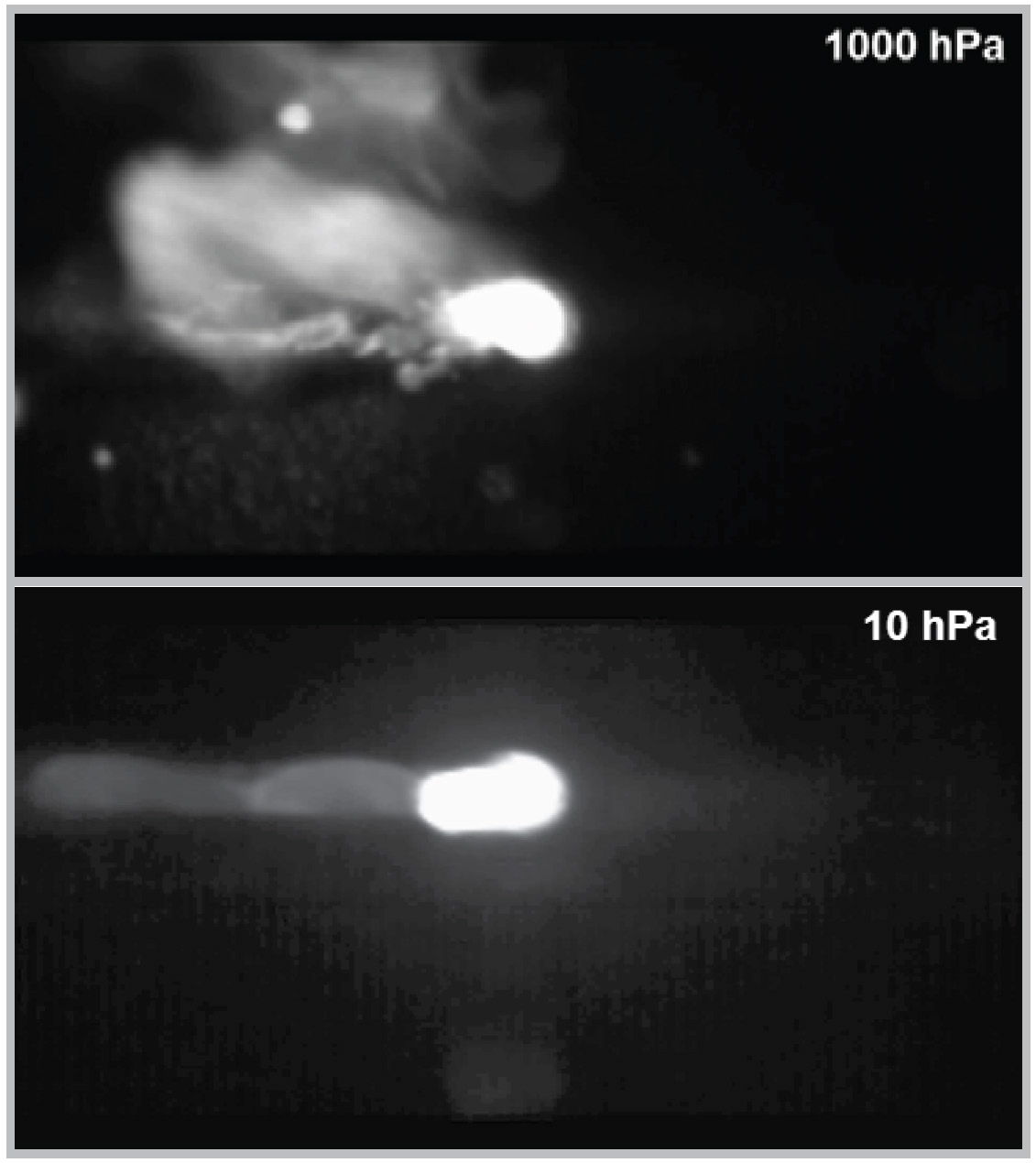

High-speed pictures show that, in the case of atmospheric welding, clear separations of spatters from the melt pool can be observed (Figure 4). In this case, escaping metal vapor exerts pulsed forces on the capillary back wall and effects a separation of spatters. At reduced pressure, the keyhole opening, especially with high feed rates, has an elongated characteristic, ensuring a free escape of the metal vapor. The metal vapor exits from the capillary without touching the back wall and ensures that the impulse responsible for spattering does not occur, or only occurs to a small extent. Due to the clearly reduced spattering as a consequence of a suppressed metal vapor plume, a modified melt pool dynamic occurs, too. At reduced pressure, the welding process is much smoother, without spilling or fluctuating movements of the liquid melt.

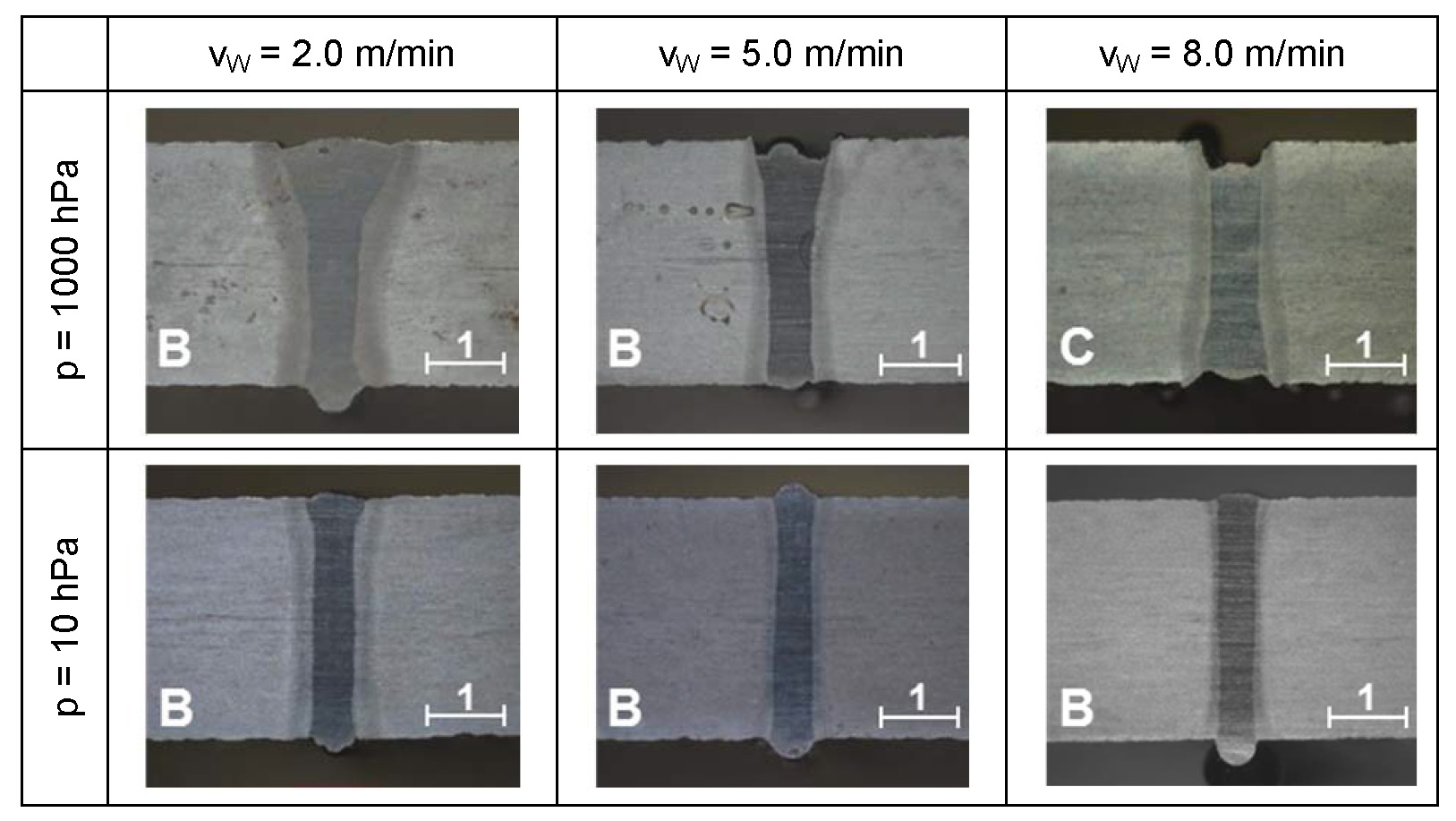

Figure 5 shows several cross sections with the indication of the fulfilled quality level according to the international standard ISO 13919-1. The speed-dependent losses of mass by spattering shown in Figure 3 before can be detected very clearly in the cross sections, due to the geometric irregularities. Under atmospheric pressure, the cross sections show only slight irregularities at 2 m/min. Irregularities increase with increasing welding speeds. The macrosections, welded with 5 m/min or more, show a large seam collapse and root relapse, which are caused by spattering. When welding under reduced pressure, the seams are of a very homogeneous quality without irregularities of seam geometry. The reason may be the formation of fewer spatters under reduced pressure resulting in reduced material loss in such a way that sufficient material is available for formation of the weld seam without irregularities. In particular, there is a significant advantage of vacuum laser welding when welding with high feed rates.

In further investigations, real components were welded by vacuum laser welding. Figure 6 shows a typical welding application in gearbox manufacturing. A clutch body is pressed on a gear wheel and afterward welded in an axial weld seam. These parts are very small — about 100 mm in diameter — and it is an ideal welding application in a small vacuum chamber. This component is welded with a feed rate of 5.0 m/min in an excellent weld quality without spatters. The cross section shows a very narrow and homogeneous weld seam with a penetration depth of 4 mm. This outstanding weld quality is absolutely not possible when welding under atmospheric conditions.

The investigations presented here clearly show that welding at reduced pressure with solid-state lasers offers an enormous potential for a quality improvement in regards to spattering and weld seam properties. The application limits of modern high-brilliance beam sources can be considerably extended with regard to their usable welding speed. Benefits are therefore economic as well as qualitative.

Due to these advantages, it can be expected that, in the next few years, the procedure — in particular in applications with the highest requirements on seam quality and low spattering — will be introduced into the market. During the current project period, the advantages of laser welding at reduced pressure have been transferred into the industry to such an extent that customers are inquiring about components welded with this procedure.

Christian Börner and Klaus Dilger are with the Institute of Joining and Welding in Braunschweig, Germany.